Agillence Lean Logistics Optimizer

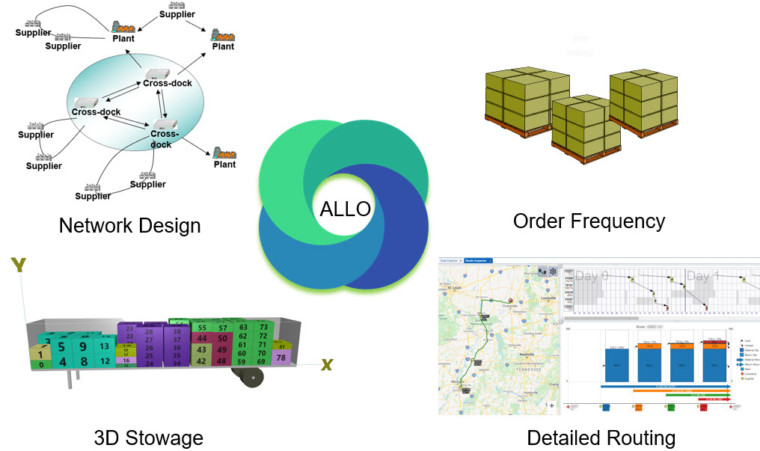

ALLO is a tool to design and plan high-frequency lean logistics network using crossdocks and milkruns. It optimizes simultaneously all aspects of the problem; network design, order frequency, detailed routing, and 3D stowage. The lean logistics is essential in industries such as automotive and retail.

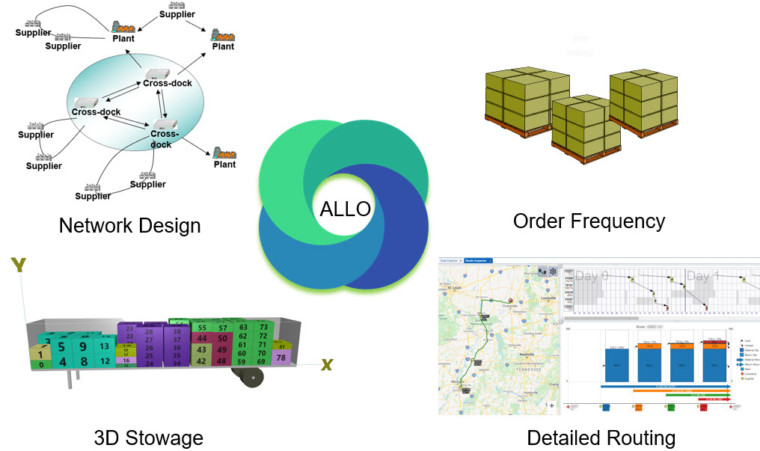

ALLO is a tool to design logistics network with crossdocks and milkruns for strategic and tactical purposes. It produces high frequency lean logistics network at low costs. Lean Logistics is characterized by high frequency replenishment and freight consolidation utilizing networks of crossdocks and milkruns. It promotes continuous flow of products from origin to destination by the pull of actual consumption and thereby eliminates wastes. The results are low inventory, high availability, resource smoothing, and improved asset utilization at low costs. It is extremely difficult, however, to design a lean logistics network due to complex constraints and astronomical possibilities. ALLO can help you to design such a lean logistics network with ease and to revolutionize your logistics network.

Inbound example of lean logistics is found in automotive industry to support JIT production. Retailers also need lean logistics, in outbound, due to store space restriction and service level requirements.

When deployed in conjunction with Agillence Logistics Management System (ALMS), clients have a seamless solution that supports the Plan-Do-Check-Act (PDCA) continuous improvement cycle.

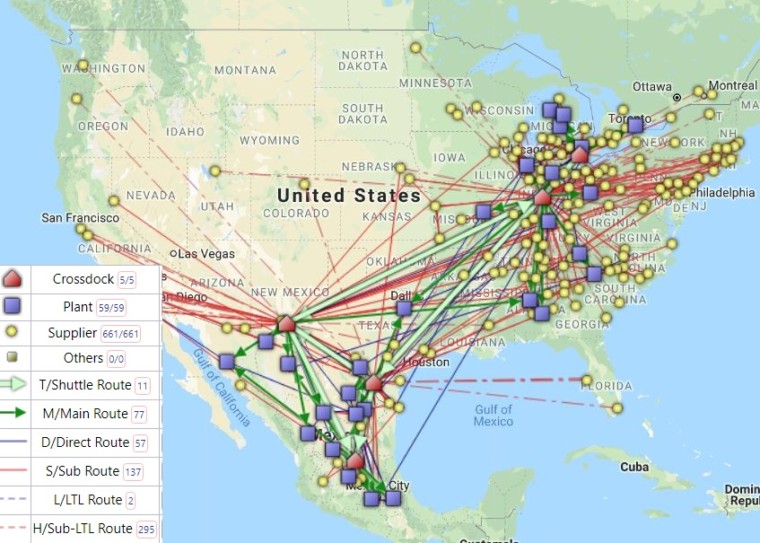

The pictures below are some of the outputs of ALLO, result of one simultaneous optimization.

The following questions can be answered by ALLO:

- How do I switch from my traditional practice with many inventory stocking points to new lean logistics

- What is the logistics cost for different leanness of the network

- What’s the impact of new plant location?

- What should be my new network to support FGP (factory gate pricing) or DSD (direct store delivery)?

- Where do I put new crossdocks and in what capacities?

- Should I use rail?

- How can I be responsive to irregular demands?

- How do I cope with higher fuel cost and stricter driving rules (Hour of Service)?

- How can I lower my inventory level while maintaining or improving service level?

- Can I generate route designs practical to carriers and suppliers?

- How do I know if my crossdock territories are optimal?

- What should be optimum pickup/delivery frequencies?

Key Features

- Simultaneous optimization of Network Design + Order frequency + Detailed Routing + 3D stowage

- Dock door and Resource scheduling

- Frequency Optimization of pickup and delivery at part level, while honoring lean constraints

- Heijunka across the network

- Support for various types of routes; Direct, Crossdock, Shuttle, LTL

- Routes close to implementation

- Pickup and delivery frequency constraint (metering from crossdock)

- Rich transportation cost modeling; mileage, stop charge, minimum charge, fixed cost, TL table, LTL table, roundtrip, one-way

- Resource based costing – driver, tractor, trailer, and mileage

- Multi-echelon – multiple legs of shuttle routes

- Leadtime constraint at part/OD level for service based networks

- Asymmetric route – different visit frequencies within the route

- Multiple time windows for stores/suppliers

- Detailed driving rules – single, team and hours of service

- Easy baselining for partial optimization and benchmarking

- Seamless integration with Agillence Logistics Management System (ALMS)

- Intuitive scenario management facilitates collaboration between group of users

- SaaS and Cloud based scalable & secured platform

- Concurrent optimization of multiple scenarios

Reference Articles

-

- Penske Logistics, LLC. Selects Agillence Inbound Optimization

- Nissan opts for Agillence TMS to manage parts logistics

- Nissan North America, Inc. Chooses Agillence Transportation Management System

- Toyota chooses network optimisation tool from Agillence

- Agillence to Provide Inbound Logistics Optimization Software to Toyota Motor North America, Inc.

- Make Technology Fit with People and Lean Processes

- Inbound Transportation Can Be Complex Too

- Prove IT, then Move IT

- Agillence to Provide Inbound Logistics Optimization Software to Toyota Motor Europe N.V.